Sprayfoam Superintendent

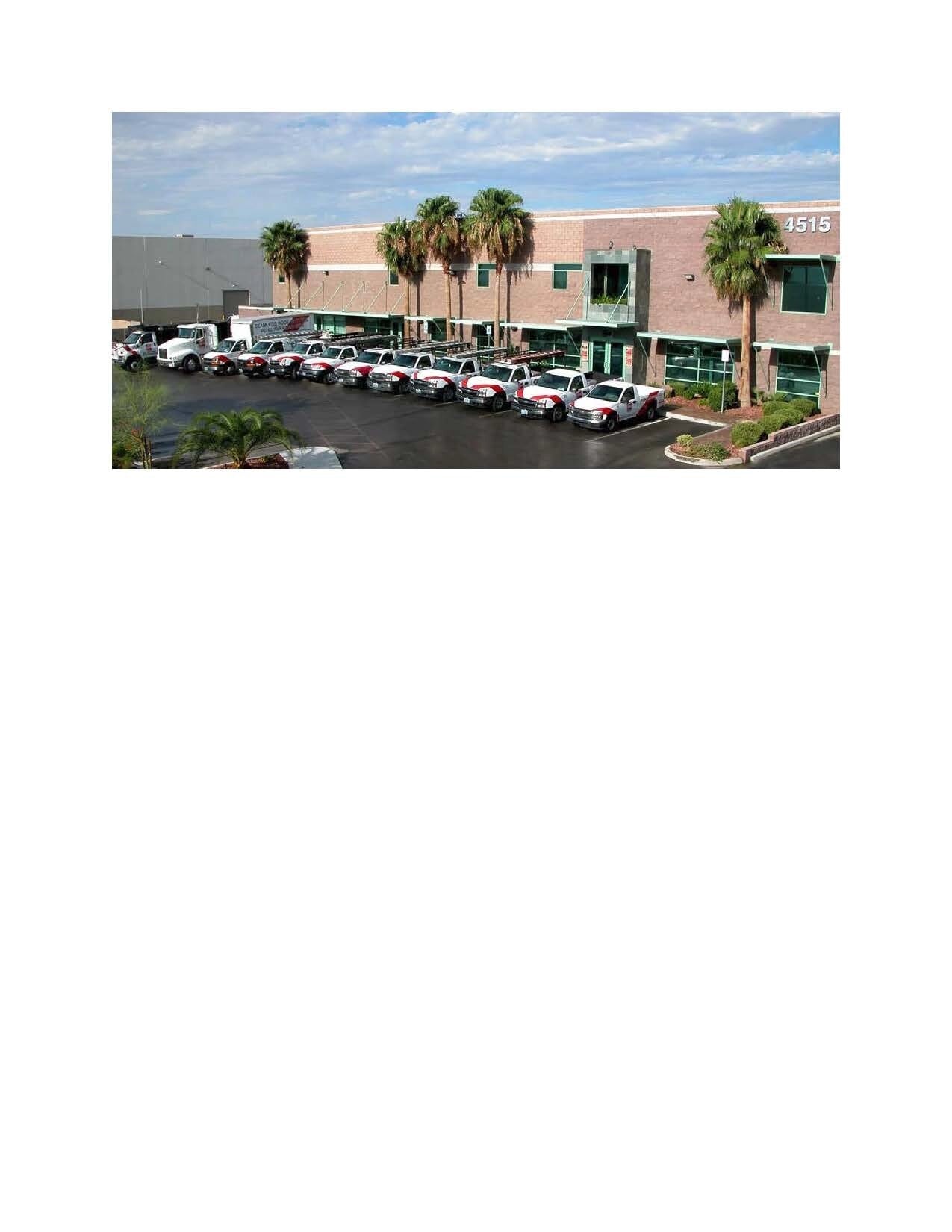

the original roofing company

The Role

Overview

Lead spray foam crews, manage schedules, safety, quality, equipment, and client coordination.

Key Responsibilities

- spray foam

- rig maintenance

- material planning

- crew scheduling

- safety enforcement

- qc checks

Tasks

The Spray Foam Superintendent leads day‑to‑day field operations for multiple spray crews using Graco spray equipment. This role plans and schedules crews, oversees safety and quality, manages rigs and materials, coordinates with customers/GCs, and ensures work is completed on time, within budget, and to spec. Ideal background includes spray foam insulation and experience with spray‑applied coatings, epoxy, or waterproofing. -Verify crew fit‑testing and medical clearances for respirators; maintain SDS books and hazard communications. -Verify substrates are clean, dry, and within spec; check ambient/substrate temps, humidity, and dew point. -Ensure professional communication and customer service on site; handle issue resolution. -Approve timecards, equipment logs, and daily reports; monitor production vs. budgeted man‑hours. -Own safety performance for assigned projects: enforce OSHA/company policies, respiratory protection, fall protection, and ventilation plans. -Document batch numbers, lot tracking, test data, and photo evidence; close punch lists quickly. -Conduct customer walk‑throughs; obtain sign‑offs and warranty documentation. -Conduct site audits and near‑miss reviews; correct hazards immediately and document. -Conduct pre‑job planning: scope review, substrate prep requirements, environmental controls, and QC plan. -Provide accurate percent‑complete updates and schedule impacts to Operations/PMs. -Coordinate access, permits, and inspections with Project Managers, GCs, site supers, and homeowners/building managers. -Ensure housekeeping, masking, overspray control, disposal of waste per regulations, and clean demobilization. -Plan material pulls and deliveries; track usage, waste, and returns against estimates. -Run daily start‑up huddles and Job Hazard Analyses (JHAs); assign tasks and production targets. -Manage Graco equipment (e.g., Reactor‑series proportioners, transfer pumps, heated hoses, Fusion/Probler‑type guns, airless sprayers). -Lead, coach, and hold accountable 1-22 field crews (lead sprayers, hose tenders, laborers). -Confirm mix ratios and settings per product data sheets; supervise in‑process checks (adhesion, density, mil thickness). -Support hiring, onboarding, and skills training for sprayers and apprentices. -Oversee rig readiness: preventative maintenance, parts inventory, calibration logs, and cleanliness. -Build weekly and daily schedules for spray crews based on manpower, equipment availability, site readiness, and weather. -Troubleshoot pressure/heat imbalance, cavitation, spray pattern, filter/packing, and hose heat issues; minimize downtime. -Safety: Zero recordables; timely reporting of observations/near misses.

Requirements

- osha 30

- spfa pcp

- spray foam

- crew lead

- graco systems

- bilingual

What You Bring

Success Metrics (KPIs) -Lift/carry 50–75 lbs; frequent standing, bending, ladder/scaffold work, and work at heights. -5+ years in spray foam insulation or spray‑applied systems (coatings, epoxy, waterproofing), with 2+ years leading crews as Foreman/Supervisor/Superintendent. -OSHA 30, First Aid/CPR, aerial lift and forklift certifications. -Early starts, overtime/weekends as needed; travel between active job sites. -Comfortable wearing full PPE including respirator and protective clothing. -Valid driver’s license with acceptable MVR; ability to tow and manage spray rigs. -Quality: ≤2% rework; pass rates on adhesion/density/mil thickness checks. -Customer: Positive site evaluations; prompt punch‑list closure. -Experience on roofs, in mechanical rooms, crawlspaces, and other challenging environments. -Strong knowledge of jobsite safety, respiratory protection, fall protection, and confined/enclosed space best practices. -Productivity: Hit or beat budgeted man‑hours and material usage; minimal waste. -SPFA PCP certification (Installer/Project Manager), NACE/AMPP or coatings QC exposure a plus. -Ability to read plans/specs, product data sheets, and QC/inspection criteria; competent with basic field math and documentation. -Schedule: ≥95% tasks completed on or ahead of plan. -Equipment Uptime: ≥98% availability of rigs; PMs completed on schedule. -Bilingual (English/Spanish) helpful. -Hands‑on proficiency with Graco systems and airless rigs (setup, operation, troubleshooting, maintenance).

People Also Searched For

Property Manager jobs in Las Vegas , Nevada , US

Sales jobs in Las Vegas , Nevada , US

General Admin & Support jobs in Las Vegas , Nevada , US

Property Manager jobs in Nevada , US

Sales jobs in Nevada , US

General Admin & Support jobs in Nevada , US

Property Manager jobs in Las Vegas , US

Sales jobs in Las Vegas , US

General Admin & Support jobs in Las Vegas , US

The Company

About the original roofing company

Nope

Sector Specialisms

sectorSpecialismFormat1

sectorSpecialismFormat2