Casting Engineer (Foundry)

Twin City Fan & Blower

The Role

Overview

Optimize and oversee sand & permanent mold casting processes for quality metal parts.

Key Responsibilities

- defect resolution

- print review

- process optimization

- equipment design

- sop maintenance

- safety compliance

Tasks

Optimize casting processes to produce high-quality metal components. This involves ensuring the efficiency, cost-effectiveness, and reliability of casting operations while maintaining strict adherence to safety and quality standards. The Casting Engineer collaborates with cross-functional teams to troubleshoot issues, implement improvements, and support the overall manufacturing goals of the organization. -Troubleshoot and resolve casting defects and production issues. -Review engineering prints for accuracy and putting in change requests when necessary. -Provide technical support and training to production staff. -Collaborate with design engineers to review product designs and recommend modifications for manufacturability. -Ensure compliance with safety and environmental regulations. -Identify areas of safety improvement and implement solutions to reduce injuries or accidents. -Oversee the production process, including mold preparation, pouring, and finishing. -Maintain and update process documentation and standard operating procedures. -Evaluate areas of quality improvement and implement solutions to reduce waste. -Implement process improvements to enhance efficiency, reduce costs, and improve product quality. -Participate in implementing new methods and systems, including preparing documentation, designing and installing new equipment, conducting training for others, and designing tests to evaluate new methods. -Optimize sand molds and cores to ensure high-quality castings. -Collaboration in design and development for sand & permanent mold casting processes for new and existing products.

Requirements

- casting

- cad

- bsc mechanical

- 3+ years

- problem solving

- teamwork

What You Bring

-Strong knowledge of casting processes, materials, and equipment. -Ability to occasionally climb, balance, stoop, kneel, reach -50% travel (if not located in Iowa). -Ability to work extended hours sitting at a computer -Ability to occasionally lift up to 20 pounds -Attention to detail and a commitment to quality. -Excellent problem-solving and analytical skills. -Minimum of 3 years of experience in sand and permanent mold casting or a similar manufacturing environment. -Proficiency in CAD software and casting simulation tools will have an advantage but not mandatory. -Bachelor's degree in Mechanical Engineering, Metallurgical Engineering, or a related field. -Strong communication and teamwork abilities. -Act, Live, and Behave by TCF Core Values.

People Also Searched For

Service Technician jobs in Minneapolis , Minnesota , US

Site Supervisor jobs in Minneapolis , Minnesota , US

Electrical Supervisor jobs in Minneapolis , Minnesota , US

Service Technician jobs in Minnesota , US

Site Supervisor jobs in Minnesota , US

Electrical Supervisor jobs in Minnesota , US

Service Technician jobs in Minneapolis , US

Site Supervisor jobs in Minneapolis , US

Electrical Supervisor jobs in Minneapolis , US

Benefits

As a Casting Engineer in our Test lab you will be offered pay of $80,000-$90,000 per year dependent on experience. You will also be eligible for an annual discretionary bonus tied to overall performance of the organization. At Twin City Fan we want our employees to achieve their personal best and strive to offer programs that support our employees and their families. We offer a full benefits package including medical, dental, vision, life insurance, 401K plan with employer match, as well as short/long term disability. Employees also have access to benefits such as employee assistance programs, education reimbursement, paid vacation, holiday pay, and volunteer time. Other exciting benefits TCF offers include a homeownership savings program, pet insurance, and more! -Standard office environment

The Company

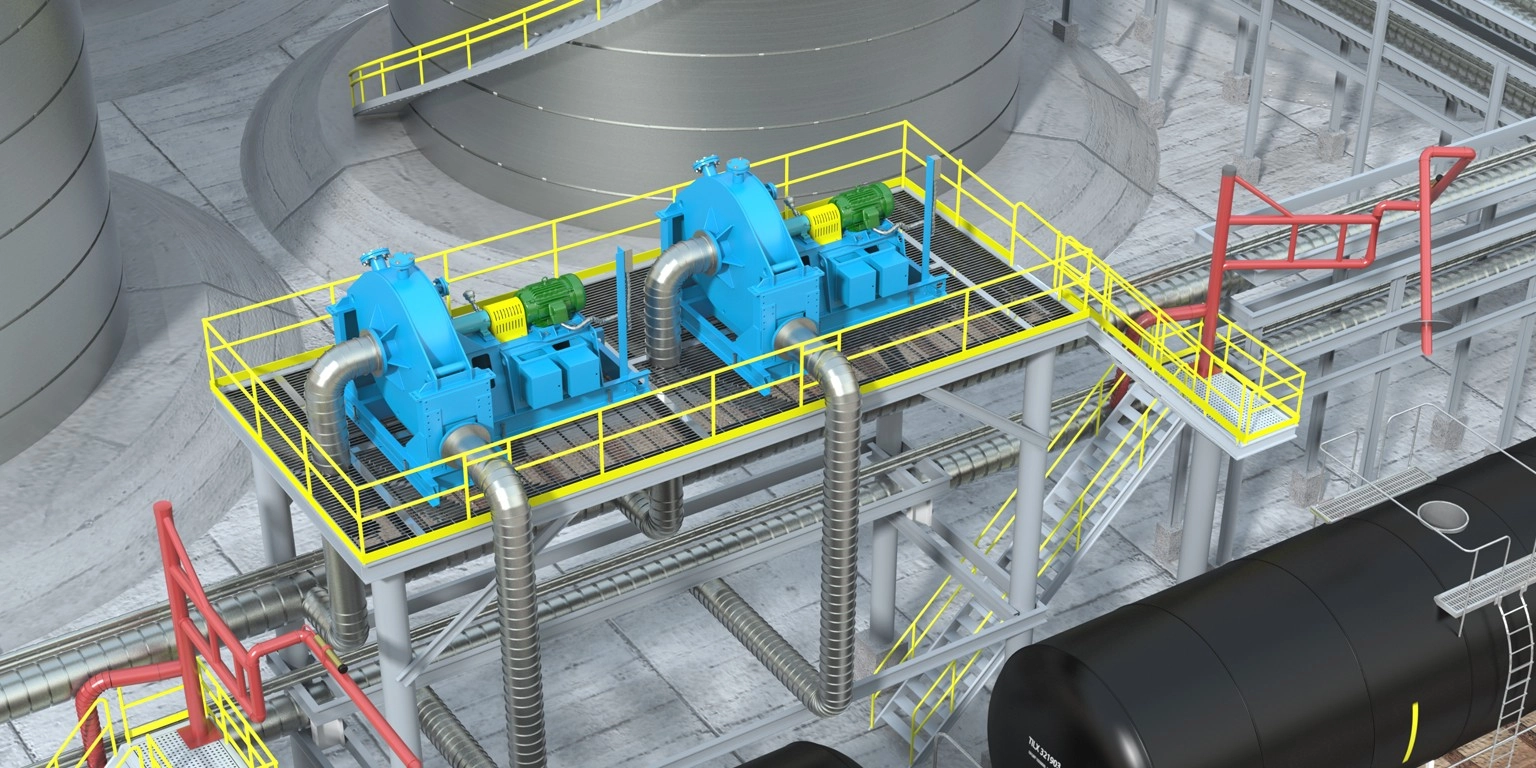

About Twin City Fan & Blower

-A leader in the design and manufacturing of custom air movement systems. -Creates high-performance fans and blowers for industries like manufacturing, commercial, and energy. -Typical projects include air handling systems, industrial ventilation, and energy-efficient solutions for various sectors. -Engineers solutions that meet complex and highly specific customer needs. -Operates with a strong emphasis on reliability, quality, and innovative design. -Has worked on projects ranging from large-scale industrial plants to commercial ventilation systems, providing tailored solutions. -Committed to advancing technology to continuously improve its product offerings.

Sector Specialisms

Industrial

Commercial

Automotive

Textile

Nuclear Power

Pulp and Paper

Food Processing

Water Treatment

Petrochemical

Oil

Agriculture

Material Handling

Coal Processing

Foundries

Tunnel Ventilation

Dust Collection

Glass

Waste Management

Chemical

Recycling

Marine

Pharmaceutical

Cement and Lime

Transportation

Ethanol

Air Pollution Control

Energy Recovery

Mining

General Manufacturing

Laboratory & Fume Hood Exhaust

Schools

Hospitals

Hotels

Restaurants

Institutional Facilities

Retail Shopping Centers

Sports Arenas and Stadiums

Airports

Data Centers

Emergency Smoke Control

Warehouses and Distribution Centers

HVAC OEMs

Government