Senior Manager - Piping Design

Rolls-Royce Smr

The Role

Overview

Lead design and delivery of reactor island piping layout for SMR projects

Key Responsibilities

- team leadership

- piping design

- technical lead

- program delivery

- cost estimate

- safety cases

Tasks

-The role will lead a large team and large budget, both of which will grow significantly in later phases of the programme. This will require substantial leadership skills and expertise to lead people with diverse backgrounds, experience, and skills, maintaining, and sustaining a SQEP resource pool to lead the project from concept to operation of the first SMRs and beyond. This role will demand leadership of people across multiple locations within the UK, and potentially globally. -Guides others in resolving complex issues in their own specialised area and solves complex problems with implications on cross-functional business processes. -Manage the team to deliver and provide assurance of the full scope of the piping layout design across Reactor Island. This includes pipe routing (including modularisation design), pipe stress analysis and piping system functional performance. -Ensure SQEP within the workforce by developing robust training plans for members of the team and ensuring succession planning for the team. -Own the design configuration of piping layout within area of accountability, integrated with the wider programme. -Identifies applications of functional knowledge and existing methodologies to complex problems. -Lead development of the team to act as intelligent customer and the design authority including people, processes and tools are in place. -Technically lead and drive their specified elements of the integrated development programme in line with the programme's policies and processes and provide technical leadership and governance for piping layout development in line with delegated authority. -Own the delivery programme for their accountable scope of supply and contribute to the creation and management of suitable design milestone schedules and budgets. -Develop design and product cost estimates, manage the wider technical attributes for their scope and contribute to the associated Installations opportunity and risk registers. -Deliver and own engineering substantiation and safety cases for agreed scope.

Requirements

- autoplant

- asme iii

- project management

- leadership

- bpss

- nuclear

What You Bring

-Experience of managing and piping layout design solutions within the nuclear industry (or similar) and/or large EPC infrastructure projects, ensuring design integrity and compliance. -Satisfactory completion of a basic financial probity check -Serves as an adviser and applies knowledge of strategies that can be used within own function and discipline. -Satisfactory completion of a Disclosure and Barring Service (DBS) check -The candidate shall demonstrable high levels of skill in project management in an engineering context will be required to understand the performance of the team, to lead the implementation of work into the higher-level reporting and generate narrative to explain the formal position of the team on a regular basis. -Experience of piping specific design codes & standards, preferable ASME III. -Obtaining Baseline Personnel Security Standard (BPSS) clearance -An exceptional team player that is prepared to support any aspect of the business when required. Display an appropriate questioning attitude and excel in periods of uncertainty within a learning culture. Is willing to work in an ever changing and ambiguous environment and flex and bend to the evolving needs of the business, sustaining exceptional leadership behaviours. -As this is a key strategic leadership role within the Installations team, the ability to work with people, build teams, create a supporting working environment, and communicate up and down the business hierarchy is a key competence that the candidate should be able to demonstrate. -Experience of leading large engineering teams and programmes to deliver complex, high integrity designs in complex business environments. -Knowledge of cross functional business collaboration needed to deliver integrated design solutions is important to coach and lead the team and ensure the design and development supports the delivery demand of the Reactor Island layout. This is especially applicable to stress analysis, process engineering and external project partners, allowing the candidate to work with, influence and direct other parts of the business to achieve successful design development and delivery of the piping layout. -Familiarity with piping layout design tools such a AutoPlant 3D. -Demonstrate self-drive and motivation, and seeking to motivate others, to deliver maturity in the piping layout development aligned to the demands of the programme.

People Also Searched For

Electrical Installation jobs in Derby , Derbyshire , UK

Electrician jobs in Derby , Derbyshire , UK

Electrical Maintenance jobs in Derby , Derbyshire , UK

Electrical Installation jobs in Derbyshire , UK

Electrician jobs in Derbyshire , UK

Electrical Maintenance jobs in Derbyshire , UK

Electrical Installation jobs in Derby , UK

Electrician jobs in Derby , UK

Electrical Maintenance jobs in Derby , UK

Benefits

-We anticipate paying a salary between £68,000 - £90,000 Dependant on Experience -Private Medical Insurance - BUPA single cover health care -Pension - 12% employer and 6% employee contributions. -Bonus - Short Term Incentive - Performance Based- target opportunity 17% -Benefits Allowance - £5,000, enabling you to create a bespoke package -Life Assurance - 6x pensionable pay -£250 - One-off payment for new starters for home office purchases -Holidays - 28 days holiday (+ public holidays) and the ability to buy or sell up to 4 days -Opportunities for career growth in a rapidly scaling business. -A flexible, inclusive, and supportive working environment.

The Company

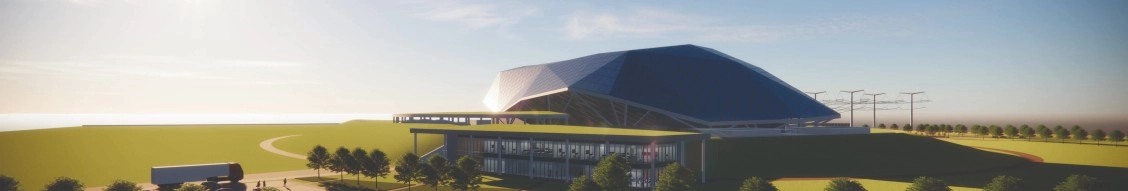

About Rolls-Royce Smr

-A team of 15 engineers at Rolls‑Royce began designing a compact, scalable nuclear solution in 2016. -Blends decades of naval reactor experience with advanced manufacturing. -Modules are nearly 90% factory‑built across 1,500 parts, then shipped and assembled on site—cutting costs, time and complexity. -The company uses a boron-free primary circuit, eliminating toxic boric acid and reducing water use and waste. -Backed by strategic investors and partners like ČEZ and Siemens Energy to support global rollout. -Positions itself as a repeatable, investable product offering dependable 'always-on' clean energy to grids and industries.

Sector Specialisms

Energy

Nuclear

Industrial

Transportation

Manufacturing

Digital Innovation

Modular Construction

Power Generation

Clean Fuels

Decarbonisation

Heat Sector

Oil and Gas

Renewables

Research and Technology

Security Clearance

-baseline personnel security standard (bpss) clearance -disclosure and barring service (dbs) check -basic financial probity check