Team Lead- Weld (Days)

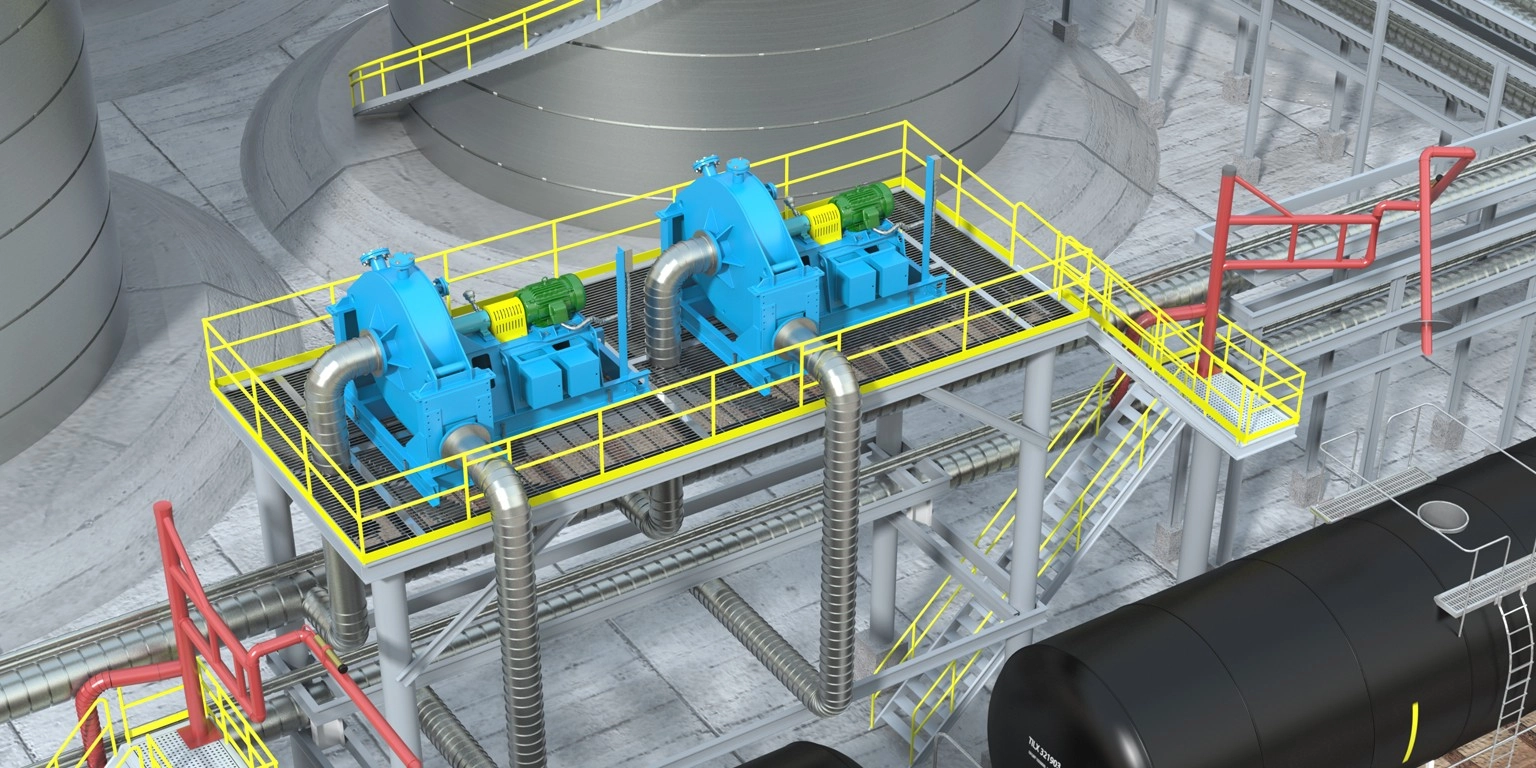

Twin City Fan & Blower

Manufacturer of custom fans, blowers, and air movement solutions for industrial applications.

Oversee weld department operations, ensuring safety, quality, training, and continuous improvement.

8 days ago ago

Intermediate (4-7 years), Junior (1-3 years)

Full Time

Brookings, SD

Onsite

Company Size

600 Employees

Service Specialisms

Engineering

Design

Technical Services

Consulting

Project Management

Turnkey

Sector Specialisms

Industrial

Commercial

Automotive

Textile

Nuclear Power

Pulp and Paper

Food Processing

Water Treatment